are various elements which condition the control signals for a task. The

elements are:

- Dual pressure valve (AND function)

- Shuttle valve (OR function)

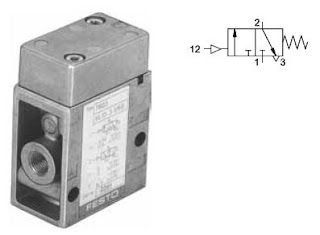

A shuttle valve permits the combination of two input signals into an OR

function. The OR gate has two inputs and one output. An output signal is

generated, if pressure is applied at one of the two inputs.

The further development of processing elements in pneumatics has

brought about the modular systems, which incorporate directional control

valve functions and logic elements to perform a combined processing

task. This reduces size, cost and complexity of the system.